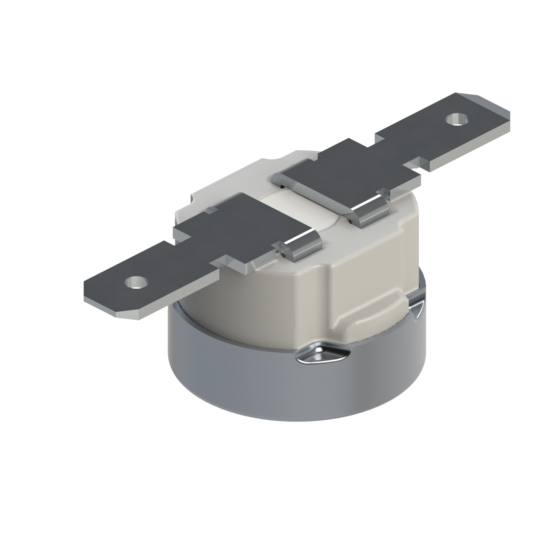

Smarty Compact

Thermostat

Tmax 200°C / Imax 10 A / orientation independent mounting / temperature resistant ceramic housing / standard terminals

Properly installed, the thermostat type 161 641 may be used wherever a fixed temperature needs to be controlled or monitored and the application makes a round thermostat necessary or desirable. The maximum ambient temperature may not exceed 200°C. The thermostat type 161 641 is tested in accordance with UL 873 and specifically approved for use in drip coffee makers.

A vaulted bimetal disc is used as a temperature sensing element. In any position, the disc is pressed directly against the mounting plate and can therefore react quickly to changes in temperature. Upon reaching the set temperature the bimetal disc operates and opens the electrical contacts. Upon cooling, the disc snaps back into its original position thereby closing the circuit again. The ceramic housing is largely closed and protects the switching mechanism against touch or dirt. It remains dimensionally stable even at high temperatures. A separate mounting clip can be ordered to fix the thermostat (one-hole design). Alternatively, a two-hole bracket is available, which can be rotated through 360° and when pressed evenly onto the aluminium cap provides a close contact to the surface to be monitored. This method of fixing must be defined when ordering as it cannot be applied subsequently. The thermostat can also be mounted by applying pressure to the top of the ceramic cover (terminal area). In order to maintain clearance, the pressure fixing element must be made of non-conductive material.

Application Advice

Heat transfer compounds should generally not be used for mounting thermostats. They frequently contain silicon which can affect the electrical contacts, leading to increased contact resistance. At high temperatures heat transfer compounds dry out relatively quickly which leads to a reduced heat transmission. Thermostats with short reaction time which are designed for the application and appropriately installed do not require such heat transfer compounds to work properly.

The advantages of Smarty Compact

Details

Technical Data

Fixed bimetal temperature controller

| Function: | Contact (n/c) opens when the temperature rises |

| Nominal current: | AC 10A, 230 V, resistive load only 100.000 cycles, type 2C AC 13,5A, 120 V, resistive load only 100.000 cycles |

| Ambient temperature: | T 200°C |

| mounting surface: | Ts 250°C |

| Switch-off temperature: | min. 50°C, max. 200°C |

| Switch-off tolerance: | ± 5 K at a switching temperature of up to 170°C ± 7.5 K at switching temperature > 170°C |

| switching differential: | 10-22K, typical 16K |

| Rate of temperature rise: | > 1K/min |

| Response speed: | Time constant approx. 5 seconds. |

| Design: | according to DIN EN 60730-2-9 protection class 1 |

| Comparative Tracking index: | PTI > 175 |

| Mark of conformity: | see the list of approvals, which is available to you on request gladly made available. |

Applications

Properly installed, the thermostat type 161 641 may be used wherever a fixed temperature needs to be controlled or monitored and the application makes a round thermostat necessary or desirable. The maximum ambient temperature may not exceed 200°C. The thermostat type 161 641 is tested in accordance with UL 873 and specifically approved for use in drip coffee makers.

Structure and mode of operation

A vaulted bimetal disc is used as a temperature sensing element. In any position, the disc is pressed directly against the mounting plate and can therefore react quickly to changes in temperature. Upon reaching the set temperature the bimetal disc operates and opens the electrical contacts. Upon cooling, the disc snaps back into its original position thereby closing the circuit again. The ceramic housing is largely closed and protects the switching mechanism against touch or dirt. It remains dimensionally stable even at high temperatures. A separate mounting clip can be ordered to fix the thermostat (one-hole design). Alternatively, a two-hole bracket is available, which can be rotated through 360° and when pressed evenly onto the aluminium cap provides a close contact to the surface to be monitored. This method of fixing must be defined when ordering as it cannot be applied subsequently. The thermostat can also be mounted by applying pressure to the top of the ceramic cover (terminal area). In order to maintain clearance, the pressure fixing element must be made of non-conductive material.

Application Advice

Heat transfer compounds should generally not be used for mounting thermostats. They frequently contain silicon which can affect the electrical contacts, leading to increased contact resistance. At high temperatures heat transfer compounds dry out relatively quickly which leads to a reduced heat transmission. Thermostats with short reaction time which are designed for the application and appropriately installed do not require such heat transfer compounds to work properly.

Advantages

- easy mounting

- rapid heat transfer and short thermal response time

- independence of the position

- high contact opening force

- closed ceramic housing and stable switching temperature under different current loads

- long service life

Approbation

see the list of approvals, which is available to you on request

gladly made available.

Applications

Downloads

List of all available downloads.

| Download file | Version | Extension | Size | |

|---|---|---|---|---|

|

Data sheet_161641

|

167 KB | Download |