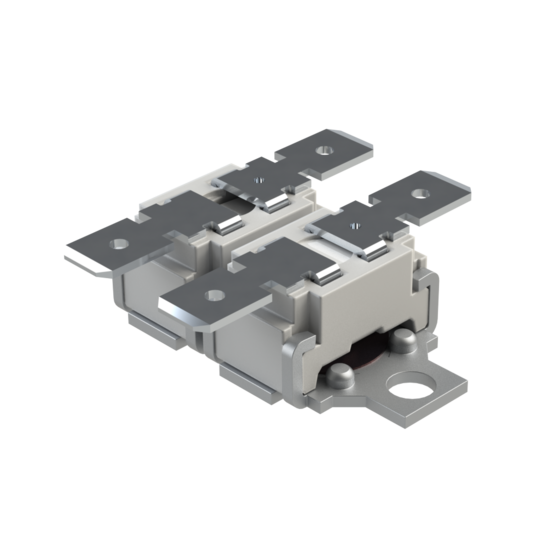

Discomelt II

Thermostat / Thermal Link Combination

Tmax 250°C / Imax 15A / short reaction time / easy mounting / orientation independent mounting / temperature resistant ceramic housing / standard terminals

Properly installed, the thermostat / thermal link combination type 161 791 may be used for applications where a fixed temperature needs to be monitored or controlled and a maximum temperature must not be exceeded, for example in household appliances such as dishwashers and washing machines, small electrical appliances such as coffeemakers, steam generators etc. or in electrically monitored water heaters.

A vaulted bimetal disc is used as a temperature sensing element in the thermostat. The disc is placed in direct contact with the

mounting plate of the combination therefore reacting quickly to changes in temperature. Upon reaching the preset temperature the bimetal disc operates and opens the electrical circuit. Upon cooling, the disc snaps back into its original position thereby closing the circuit again. The switching temperature is freely selectable within a wide range. The thermal link, approved in accordance with DIN VDE 0821 / EN 60691, has a solder insert in the mounting plate which is in direct thermal contact with the surface that is to be monitored. When the preset temperature is reached, the solder melts causing a pin to move which results in the electrical contacts opening. Resetting is not possible. 5 different preset solder temperatures are available. The two components thermostat and thermal link have a common mounting plate, which is responsible for thermal conduction. This ensures that the thermal information for thermostat and thermal link always comes from exactly the same source.

The advantages of Discomelt II

Details

Technical Data

fixed Thermostat / Thermal Link Combination

| Nominal voltage / current: | AC 10 A, 230 V or 13,5 A, 120 V non-inductive load, 100,000 cycles |

| Maximum temperature: | T 200 °C (T 250 °C on request) |

| Nominal switching temperature: | 50 – 200 °C (up to 250 °C on request) |

| Switch-off tolerance: | ± 5 K |

| Differential: | < 25 K |

| Rate of temperature rise: | > 1 K/min |

| Design: | according to DIN EN 60730 protection class I |

| Proof tracking index: | PTI 175 |

| Mark of conformity: | refer to approvals list which is available on request |

Technical details for thermal link: see enclosure

Applications

Properly installed, the thermostat / thermal link combination type 161 791 may be used for applications where a fixed temperature needs to be monitored or controlled and a maximum temperature must not be exceeded, for example in household appliances such as dishwashers and washing machines, small electrical appliances such as coffeemakers, steam generators etc. or in electrically monitored water heaters.

Structure and mode of operation

A vaulted bimetal disc is used as a temperature sensing element in the thermostat. The disc is placed in direct contact with the

mounting plate of the combination therefore reacting quickly to changes in temperature. Upon reaching the preset temperature the bimetal disc operates and opens the electrical circuit. Upon cooling, the disc snaps back into its original position thereby closing the circuit again. The switching temperature is freely selectable within a wide range. The thermal link, approved in accordance with DIN VDE 0821 / EN 60691, has a solder insert in the mounting plate which is in direct thermal contact with the surface that is to be monitored. When the preset temperature is reached, the solder melts causing a pin to move which results in the electrical contacts opening. Resetting is not possible. 5 different preset solder temperatures are available. The two components thermostat and thermal link have a common mounting plate, which is responsible for thermal conduction. This ensures that the thermal information for thermostat and thermal link always comes from exactly the same source.

Advantages

- easy mounting

- both components mounted onto one base plate with homogenous heat transfer

- very fast response time thanks to integrated solder strut in the base plate

- protected contact system, no cover cap necessary

- large variance in different, discreet fuse temperatures from Tf 206°C up to 318°C

- high continuous operating temperature Th

- high contact opening force

- high dielectric strength and long lifespan

- consistent performance characteristics and product quality through fully automated production

Approbation

refer to approvals list which is available on request

Applications

Downloads

List of all available downloads.

| Download file | Version | Extension | Size | |

|---|---|---|---|---|

|

Data sheet_161791

|

822 KB | Download |