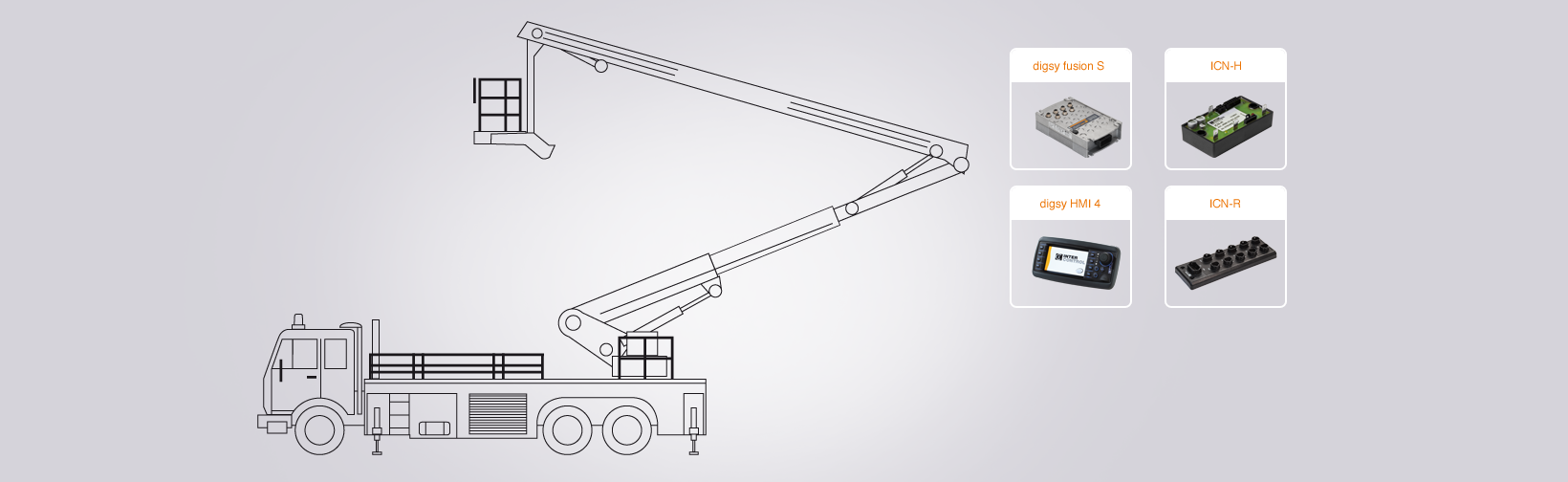

Machine specific functions

Functions of the vehicle:

- Decentral control of the outtriggers with feedback via CAN nodes

- Auto leveling

- Storage and analysis of the outtrigger configuration

- CAN communication to the cage

- Operator panel in lower operator stand with color monitor on the switching panel

- Acquisition of the sensor signals: rotation angle, erecting angle and telescope length

- Storage of the load tables

- Motion control with ramp functions based on the load tables

- Weight determination by pressure sensors with appropriate logical processing

- Joystick data processing in real time

- Hydraulic valve control with PWM signals

- Complete J1939 control for Engine ECU

- Color visualization of all current data and set values

- Real time analysis of all sensors and command devices

- Real time control of the actuators

Functions of the lifting cage:

- 10" color display in control stand

- Auto leveling of the cage

- Camera input of up to 6 cameras to display areas that are not directly visible

Control specific functions

- CAN Bus technology (CANopen, J1939, CANopen Safety, CLLI)

- Sensor connection to distributed CAN nodes

- Cost-effective line installation with CAN avoids complicated cable harnesses.

- The across-the-board controller system connects sensors, command devices, hydraulic valves and drive motors.

- Instead of single component selection, the system concept is prepared by a single source provider -

INTER CONTROL - Weather-protected mobile controllers and CAN I/O modules can be mounted inexpensively without switching cabinets

- Robust, scratch-proof, touch display can be operated with gloves

- Color display operator control with language-neutral icons

- Extensive process data memory up to 4 GB

- USB stick, LAN or RS 232 for data transmission to stationary PCs

- Operating and production data analysis and storage